The wiring of the motor is a very important work in the installation of the motor. Before wiring, you should understand the wiring circuit diagram of the design drawing. When wiring, you can connect according to the wiring diagram in the motor junction box.

The wiring method varies. The wiring of the DC motor is generally indicated with a circuit diagram on the cover of the junction box, and the wiring diagram can be selected according to the excitation form and load steering requirements.

Except that the dragged load has strict requirements on the steering, even if the wiring of the AC motor is reversed, it will only make the motor reverse without damaging the motor. However, if the excitation winding and the armature winding of the DC motor are directly opposite to each other, it may cause the motor armature to be electrified, and the excitation winding may be demagnetized when the motor is not electrified, so that the motor may fly when it is no-load, and the rotor may burn out when it is overloaded. Therefore, the external wiring of the armature winding and the excitation winding of the DC motor cannot be mutually staggered.

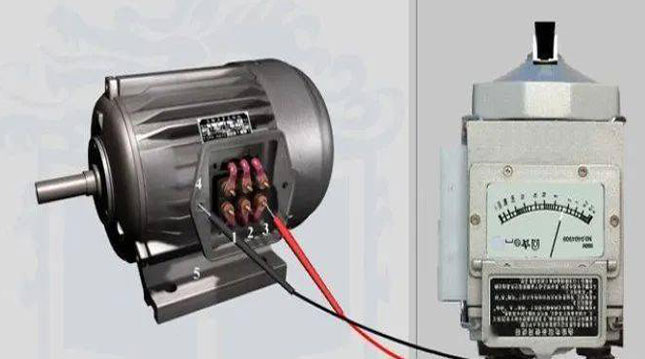

External wiring of the motor. Before connecting the external wires to the motor, check whether the lead ends of the windings in the end cover are loose. When the crimping screws of the internal lead wires are tightened, the shorting strips can be connected according to the required wiring method, and the external wires can be crimped.

Before wiring the motor, the insulation of the motor should also be checked, and the single commissioning inspection of the motor should be completed before wiring. When the motor meets the requirements of the current specification, the external wiring should be connected. Generally, the insulation resistance of low-voltage motors is required to be greater than 0.5MΩ, and the shaker should use 500V.

After the motor is installed and wired, the following inspections should be carried out before the motor is commissioned:

(1) The civil works have been cleaned and sorted out;

(2) The installation and inspection of the motor unit are completed;

(3) The debugging of the secondary circuits such as the motor control circuit is completed, and the work is normal;

(4) When moving the rotor of the motor, the rotation is flexible and there is no jamming phenomenon;

(5) All the wiring of the main circuit system of the motor is fixed firmly without any looseness;

(6) Other auxiliary systems are complete and qualified. Among the above six items, the installation electrician should pay special attention to the fifth item. The main circuit system mentioned here refers to all the main circuit wiring from the power input of the power distribution cabinet to the motor terminal, which must be firmly connected.

Air switches, contactors, fuses and thermal relays, the upper and lower contacts of the terminal block of the power distribution cabinet and the motor wiring must be crimped firmly to ensure the operation of the motor, otherwise, there is a danger of burning the motor.

When the motor is in trial operation, it is necessary to monitor whether the current of the motor exceeds the specified value and record it. Also, check the following items:

(1) Whether the rotation direction of the motor meets the requirements. When the AC motor is reversed, the two motor wirings can be exchanged arbitrarily; when the DC motor is reversed, the two armature voltage wirings can be exchanged, and the two excitation voltage wirings can also be changed.

(2) The sound of the motor running meets the requirements, that is, there is no friction sound, screaming, jamming sound and other abnormal sounds, otherwise it should be stopped for inspection.